Working in today’s highly competitive field of engineering certainly demands speed, exactness, and the ability to adapt quickly above everything else. Sequential design methods that are stiff and unforgiving are simply behind the current times!

To put it differently, engineers today must possess a CAD program that not only handles the design of complex virtual models but also allows to quickly refine designs. The program should easily manage specific production processes , such as sheet metal work. ASCON solutions KOMPAS-3D comes forward as the perfect answer to address this essential need.

You will see how this well-regarded, independent CAD powerhouse offers designers a competitive advantage. This article offers a close examination of its two core pillars of strength. We will look at its robust parametric modeling, which turns one single design into infinite product lines.

Also, we’ll examine its precise, specialized tools for sheet metal design, ensuring that every model you create is perfect for the production line.

KOMPAS-3D

Starting Price

$ 3150.00

Before diving into the core features, it’s worth understanding the foundation of ASCON’s KOMPAS-3D. This is not just another ordinary program built on someone else’s technology. It’s in fact a self-sufficient, proven solution that brings significant advantages to the user.

ASCON’s KOMPAS-3D CAD has been available for sale in the market for decades now. The software has demonstrated excellent reliability and stability over time. It has earned the complete trust of a very large community of users having reached >400.000 installations. Let’s look at why it continues to be popular among its users:

Proprietary Kernel:

It operates using its own geometric kernel and parametric technologies, developed by ASCON specialists. This makes the software solution independent and exceptionally reliable for technical tasks, ensuring better security and flexibility compared to platforms reliant on external kernel technologies.

Perpetual Licenses:

In a market dominated by subscription models, KOMPAS-3D CAD stands out by offering perpetual licenses. You buy it once, and you own it forever. Its flexible upgrade policy allows users to purchase upgrades at any time only if they need it. This significantly contributes to a lower Total Cost of Ownership (TCO), saving money compared to other popular CAD tools over the long run.

The power of ASCON’s KOMPAS-3D CAD is evidenced by its broad application across essential global industries. It’s not limited to one sector.

Manufacturing Diversity:

It is widely used in:

Parametric modeling is the backbone of efficient modern product design. It’s what separates a static drawing from a dynamic, adaptable blueprint. KOMPAS-3D excels here, allowing engineers to create products that are defined by relationships and parameters, not just fixed geometry.

What does it truly mean to use parametric modeling? Well, it means the dimensions, features, and locations within your model are tied to adjustable numerical parameters.

Quick Geometry Adjustment:

If you need to design an entire product family, like motors, you skip redesigning every single size. You only need to adjust one single variable (for example, the diameter of the motor casing). The software will then automatically rebuild and recalculate the entire component based on established relationships. These relationships dictate, for instance, that bolt hole centers must stay 10 mm from the edge always.

Design Variations:

This technology allows for the easy creation of multiple design variations from one model. This capability is absolutely crucial for creating comprehensive product lines or quickly customizing parts for a specific client requirement. You use a once-designed prototype as a base for typical products.

Flexible Design Approaches:

The software offers engineers the freedom they need by supporting flexible design methods:

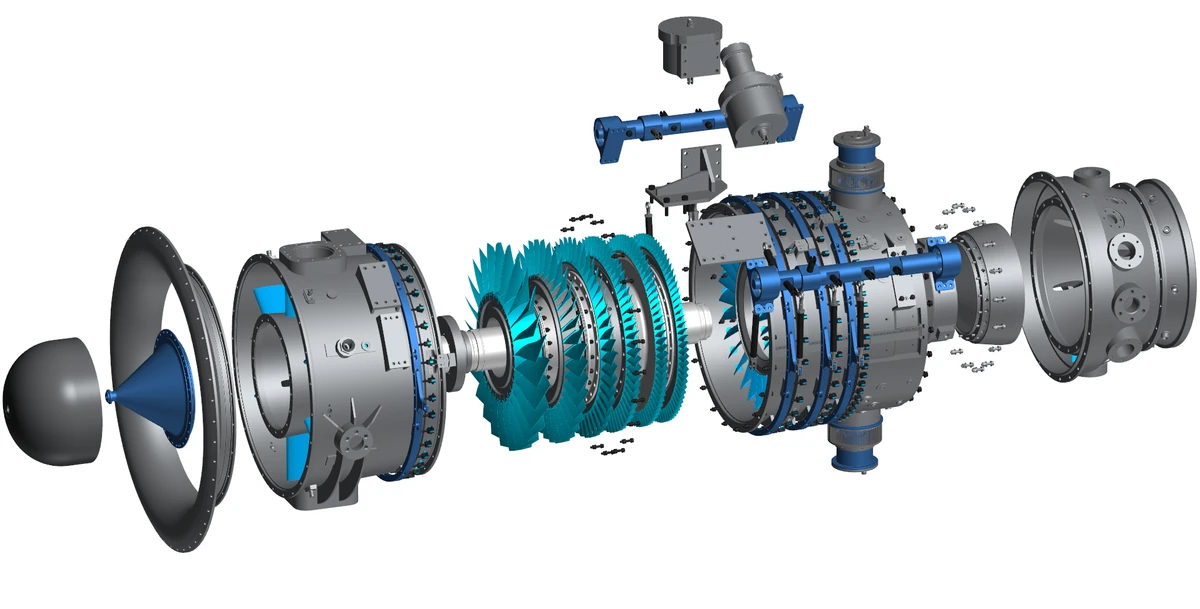

For heavy equipment, aerospace components, or large machinery, the model often contains thousands of parts. KOMPAS-3D is built to handle this complexity without slowing down the workflow.

Robust Project Management:

The system has powerful functionality and unprecedented stability for managing projects containing thousands of sub-assemblies, parts, and standard products.

High Productivity:

It is recognized as a fast and powerful tool, offering optimal functionality and extensive automation capabilities to handle these big, complex projects efficiently with modest system requirements.

Sheet metal fabrication is a specialized field with unique demands, especially the need to generate accurate flat patterns from complex 3D bend designs. KOMPAS-3D CAD provides dedicated, sophisticated tools for this precise manufacturing process.

The software includes features that cater specifically to the geometry and process constraints of sheet metal work. Here’s what it offers:

Design and Flattening:

It is specifically designed for creating sheet metal parts, allowing users to model bends, flanges, and cuts in 3D. Most importantly, it includes dedicated functions for generating flat patterns from designs for production. This process is vital for the manufacturing stage.

Versatile Modeling:

Sheet metal design is integrated within the overall versatile 3D modeling approaches supported by KOMPAS-3D, which also include solid, surface, and object modeling. This covers a wide range of mechanical and industrial needs.

In sheet metal design and assembly, errors are often costly. KOMPAS-3D features built-in checks to ensure manufacturability and help streamlining the final documentation phase.

Quality Assurance Tools:

Automated Documentation:

You can access frictionless documentation features within the software solution. It creates 2D drawings, specifications, bills of materials, and diagrams on its own, and they remain linked with the 3D models.

This certainly saves significant time previously spent on manual drawing tasks. Also, it ensures that all production documents remain consistent with every new design update. The KOMPAS-Graphic tool comes for making these high-quality technical documents.

The benefits of ASCON’s KOMPAS-3D solution extend beyond mere modeling. The platform integrates a wealth of engineering tools and libraries that reduce reliance on external software and enhance overall project quality.

Engineers often spend time leaving their CAD environment to use calculators or look up standard parts. KOMPAS-3D keeps them focused by bringing those tools inside the program.

Built-in Analysis:

The system provides engineering tools and calculators for:

This built-in capacity reduces reliance on external tools during the initial design phase.

Standardization and Rich Libraries:

The platform contains rich libraries and standardization features. It has extensive databases and special add-ons allowing to easily model:

This simplifies part selection and ensures adherence to recognized industry standards, improving efficiency and quality assurance.

Specialized Automation:

Tailored modules (e.g., Pipelines 3D, Unwrap, Mechanics: Springs, 3D Shafts & Gears) are available to automate complex engineering tasks, providing a massive productivity boost for specific industry applications.

Modern design workflows require strong compatibility and the ability to visualize and simulate performance before a physical prototype is built.

Enhanced Compatibility:

The software is designed for enhanced collaboration because it works with data from other CAD systems. This makes it significantly easier to collaborate with partners or clients who may be using different software environments.

CAE add-ons:

It provide realistic visualization & simulation capabilities:

These tools enable better decision-making by predicting how the design will perform under real-world conditions.

The global market today demands a lot. The best platform is one that cuts down the design time while improving precision. Here’s why KOMPAS-3D stands out as a uniquely powerful solution:

1. Streamlined Workflow:

KOMPAS-3D is not just a collection of features; it’s an optimized workflow. It combines modeling, analysis, automated documentation, and extensive automation in one platform.

2. Reduced Design Cycles:

This integration (as mentioned above) reduces the time needed for design cycles, increases accuracy, and significantly enhances innovation within the engineering team. This provides a direct competitive advantage in speed and quality.

3. User-Centric Design:

In addition to built-in learning tools, free Online Academy, and YouTube tutorials, the platform itself is incredibly simple to use, offering toolbars you can customize, easy shortcuts, and a command search function. This makes the system highly adaptable for both people who are new to it as well as those who are long-time experts familiar with popular CAD systems.

Conclusion

The future of product creation is entirely dependent on the speed and accuracy of the tools available to engineers right now. KOMPAS-3D, a solution from ASCON, has clearly secured its place as a reliable and strong player in the world of CAD. Its value comes from concentrating on crucial areas: incredible parametric modeling power and specialized features making designs ready for production.

The platform’s proprietary technology offers financial peace of mind through a lower TCO and perpetual licenses. More importantly, its advanced parametric capabilities allow engineers to manage complexity and create vast product families quickly.

The dedicated tools for sheet metal design, combined with integrated analysis and automatic documentation, ensure that the virtual model is robust, manufacturable, and perfectly documented.

All in all, ASCON’s KOMPAS-3D is the comprehensive solution that allows engineers to move faster, reduce errors, and ultimately design better products. It is a reliable choice for any business serious about engineering excellence.

Apply for a free trial to discover how KOMPAS-3D can transform your design processes.

Holi is one of the most colorful festivals, and naturally, everyone wants great photos to… Read More

Taking care of tax needs for handful of accounts is exhausting already! Now if… Read More

Facebook is more than just social platform; it’s a massive library of engaging video… Read More

It stands to reason that precise data reporting is the core of any smart business… Read More

You no longer have to be reliant on an IT help desk for every minor… Read More

Shift scheduling defines the quality of every working individual's workday more than most leadership teams… Read More