Why Your Logistics Business Needs a Yard Management System?

Have you ever had a truck sit out at your facility for hours just because nobody knew where to direct it?

It’s one of the typical pictures in the logistics yards that have not updated to automatic tracking and dispersed communication yet.

Although warehouses and transport systems tend to be highlighted, the yard is where the bottlenecks may occur.

These could be missed slots, long queues, idling trucks, and impatient drivers, and such delays can roll through your entire supply chain. Here is where a Yard Management System (YMS) comes in. Whether it is monitoring trailers and dock planning, or optimizing gate check-ins, YMS brings coordination and visibility to chaotic logistics.

We will explain in this blog what yard management is, how a yard management system functions, and why businesses are moving toward this!

What Is Yard Management in Logistics?

In logistics, yard management is a disciplined control of trailers, containers, gates, docks, vehicles, and employees within the yard of a facility, whether a distribution center, a manufacturing plant, or a port terminal.

Whereas warehouse management deals with the inventory within the facility, logistics yard management makes everything functional beyond the four walls.

Typical Yard Workflows Include:

- Gate Check-In and Check-Out: Recording arrivals and exits of the vehicle, checking documentation, and designating docks.

- Staging: Putting trailers in temporary storage to maximize the use of docks before loading/unloading.

- Yard Switching: Transferring the trailers of one zone to another with the help of yard trucks or hostlers.

- Dwell Time Monitoring: Tracking how long trailers remain idle to identify bottlenecks and inefficiencies.

Newton SCM

Starting Price

Price on Request

Common Yard Management Challenges

- Paper-based, manual checklists and gate procedures that lack accuracy and are time-consuming.

- Inability to see the location, status, and dwell time of trailers.

- Lack of communication between yard personnel, warehousing, and carriers.

- Inability to scale at high operations because of the decentralized tracking processes.

Not only do they hamper the speed of the operations, but they also lead to detentions, labor overheads, and missed delivery SLAs. This is a reason why digital transformation with the help of the Yard Management System is essential.

What Does a Yard Management System Do?

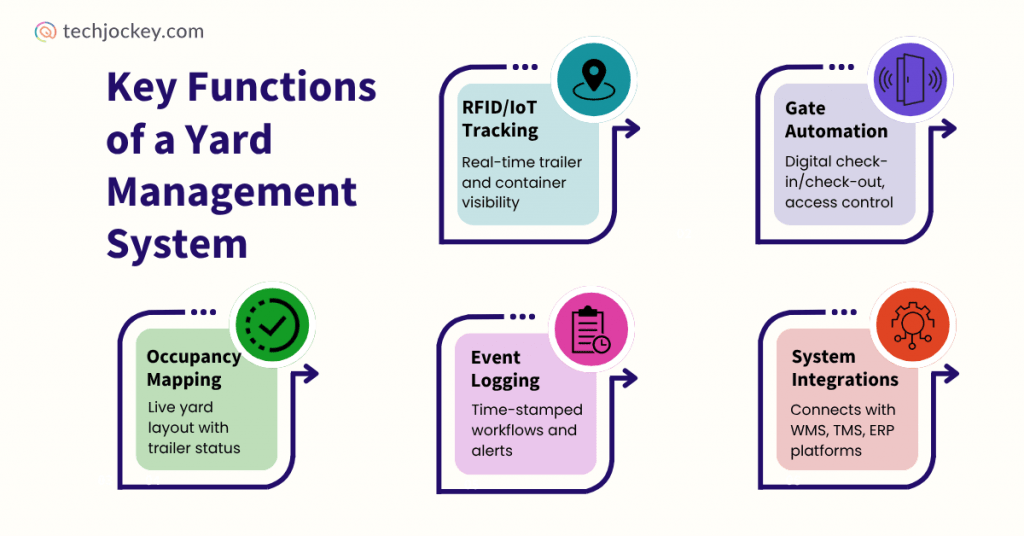

A yard management system (YMS) is a software system that aims to streamline yard management by delivering real-time data, automated processes, and integrations with other supply chain management software. A group of icons with text

Here’s a closer look at what a modern yard management system does:

- Real-Time Trailer and Container Tracking: Logistics managers can easily track the movement of trailers, their dwell, and location using the RFID tags, IoT sensors, and GPS. It guarantees that the assets are in the right place where they belong. This minimizes loss of goods due to misplacement and loss of time.

- Gate Automation and Access Control: Digital gate check-in/check-out configuration enables drivers to have self-registration, scan credentials, and receive dock assignments without any manual assistance. This results in better entry/exit workflows and makes sites more secure.

- Yard Occupancy Mapping and Heatmaps: High-performance yard management systems present a graphical overview of the yard map, indicating the position of occupied slots, idle equipment, and moving trailers. Heat maps can identify congested areas and perfect routing.

- Event Logging and Performance Analytics: Every action or communication in the yard is documented in real time. These logs are used in analytics dashboards, allowing the teams to find bottlenecks, measure staff productivity, and make data-driven decisions.

- Integration with TMS, WMS, and ERP: A YMS is a connection between transportation, warehousing, and enterprise systems. The data can easily move between platforms through API-based or EDI-based integrations. It facilitates coordinated supply chain-wide decision-making.

Newgen SCM Solutions

Starting Price

Price on Request

Key Functional Modules of a Yard Management System

Each module of the yard management system solves a particular operation requirement and functions well within the entire supply chain tech stack.

- Dock Scheduling Module: This module handles appointment-based slot booking and allows logistics teams to optimize the usage of docks. The carriers may pre-book, which mitigates bottlenecks and overlaps. Smart scheduling engines also consider the trailer type, load type, and priority shipments.

- Gate Management Module: Eliminates paper logs and manual verification with digital check-in/check-out, license plate identification, and driver credentials. Queue management algorithms improve optimization and reduce delay at the entry/exit points.

- Yard Visualization Module: An interactive, real-time digital twin of the yard displaying up-to-date trailer location, slot location, and equipment movement. Drag-and-drop capability assists in dynamically reallocating the trailers or containers based on real-time events or urgent loads.

- Reporting & Analytics Module: The module gathers operational information and provides practical insights through dashboards and KPIs visualization. Logistic managers can improve performance by using key indicators such as dwell time, usage of yard trucks, gate turnaround, and appointment compliance.

Intelex Vendor Management

Starting Price

Price on Request

Benefits of Deploying Yard Management Software

Here are a few benefits of using a yard management system:

- Operation Efficiency: YMS cuts gate-to-gate time, automating the movements of trailers through automating dock assignments and a minimum level of manual intervention. This increases the yard throughput and reduces congestion.

- Data-driven Optimization: Logistic teams can use predictive analytics with real-time and historical data to make decisions regarding yard optimization and workflows.

- Real-Time Visibility: Real-time status of trailers, their containers, and availability of yard trucks enables dispatchers and warehouse managers to stay coordinated. It avoids time wastage, minimizing idle resources and maximizing responsiveness.

- Security and Compliance: Sophisticated YMS systems have the capabilities of audit trail, access control, and geo-fencing to ensure compliance standards and enhance safety in the yard. This is particularly crucial in regulated cargo, e.g., pharma/chemicals.

Technical Architecture of Yard Management System

The YMS recently developed is designed to be agile, interoperable, and real-time responsive. They have a technical backbone that is designed to provide scalability and integration with the wider supply chain infrastructure.

1. Cloud-Based vs. On-Premise YMS Platforms

- Cloud YMS: Offers quick setup, update, and access. Suitable for multi-location businesses that require remote control.

- On-premises YMS: Recommended where operations are stricter in their data control policies or need custom security features.

2. IoT, RFID, GPS, and Geofencing Integration

Modern YMS solutions use a combination of:

- Real-time tracking of assets with the use of RFID tags and readers.

- IoT sensors to monitor trailers, gates, and yard equipment continuously.

- GPS, geofencing to automatically record movements of the trailer and provide alerts in case assets are entering/exiting designated areas.

3. API-Driven Integration with Supply Chain Systems

A modern YMS connects with Warehouse Management Systems (WMS), Transport Management Systems (TMS), and ERP platforms via APIs or EDI. This integration provides a coordinated operational picture of the warehouse, yard, and fleet.

4. Mobile and Driver-Facing Applications

To support contactless and flexible operations, many YMS solutions offer mobile apps for:

- Yard jockeys for trailer moves and checklists

- Drivers for self-check-in, load status, and dock assignments

- Managers for real-time alerts and approvals on the go

These capabilities make the YMS not only a control center but also an active part of the digital supply chain.

Top Yard Management Software Platforms in 2025

The emergence of digitized logistics ecosystems is such that a well-chosen yard management system can make or break the efficiency of operations. Here is a comprehensive list of some of the best yard management solution providers:

1. Manhattan Associates YMS

Deployment: Cloud-native

Key Features:

- Real-time trailer tracking

- Automated yard dispatching

- AI-powered dock scheduling

Strength: Seamless integration with Manhattan’s WMS and TMS for end-to-end visibility

Best for: Enterprise warehousing + transport

2. Oracle Yard Logistics

Deployment: Cloud and on-premise

Key Features:

- Gate automation

- Carrier appointment scheduling

- Customizable workflows

Strength: Deep integration with Oracle SCM Cloud and analytics for high-volume logistics networks

Best for: Large, complex logistics networks

3. FourKites Dynamic Yard

Deployment: SaaS (cloud-based)

FourKites

Starting Price

Price on Request

Key Features:

- Yard visibility through GPS and RFID

- Predictive ETAs

- Live gate operations

Strength: Strong analytics and visibility tools integrated with the broader FourKites visibility platform

Best for: Real-time tracking + analytics

4. Zebra MotionWorks Yard

Deployment: On-premise and edge-based solutions

Key Features:

- RFID and real-time location tracking

- Automated asset identification

- Zone-based analytics

Strength: Hardware-software synergy using Zebra’s IoT devices for high-fidelity asset tracking

Best for: Manufacturing and RFID-heavy yards

5. PINC YMS

Deployment: Cloud-based

Key Features:

- AI-driven yard orchestration

- Autonomous trailer management

- Mobile apps for drivers

Strength: Scalable and automation-ready for distribution centers, retail hubs, and 3PLs

Best for: Retail, distribution, 3PL

Conclusion

In a time when supply chains are increasing to be rapid, intelligent, and adaptable, the yard could no longer work as a standalone entity.

Yard Management Systems (YMS) is a digital bridge that links transportation, warehousing, and real-time orchestration of the logistics. A YMS with the ability to automate repetitive actions, enhanced visibility, and interconnected to supply chain management software drastically decreases operational bottlenecks, detention expenses, and man-hours.

It gives logistics teams data to operate quickly, program appropriately, and expand operations effectively.

Mehlika Bathla is a passionate content writer who turns complex tech ideas into simple words. For over 4 years in the tech industry, she has crafted helpful content like technical documentation, user guides, UX content, website content, social media copies, and SEO-driven blogs. She is highly skilled in... Read more