Summary: There are multiple types of stock management methods to control and manage inventory including periodic and perpetual inventory management. These methods help to track inventory in real-time, record sales and purchase order entry, update stock, and more. Read more about stock control methods in the blog below.

Inventory management falls among the most efficient business practices of all time. For centuries, inventory management has existed, from tallying sticks and stones to maintaining cattle records to using UHF RFID to track stock.

The rise of eCommerce, quick delivery, and digitization has made inventory management more crucial than ever. However, the use of Inventory management system is not limited to preventing out of stock situations these days.

Inventory management enables companies to cut costs, reduce wastage, eliminate damage, allocate resources, improve visibility, transparency, and much more. Let’s have a detailed look at inventory management, its types, techniques, and methods.

What is Inventory Management?

Inventory management is an organized system of ordering, recording, and tracking the stock items of any business. It is an essential component of supply chain management that helps businesses maintain the inflow, circulation, and outflow of raw material and finished products.

Inventory management control enables businesses to keep track of batches, set reorder alerts, provide real-time information of stock-in-hand, and more. As a result, it effectively cuts costs and ensures a smooth flow of products from procurement to selling. It also helps businesses in tracking expiries, maintaining the stock level, and reducing wastage.

Different Types of Inventory Management Methods

There are mainly two types of Inventory management based on the frequency of recording and updating stock levels.

- Periodic Inventory Management

The stock items are updated only in a specific time interval in periodic inventory management, monthly, quarterly, or yearly. Thus, periodic management is more like inventory counting than a method of inventory control.

The total stock is calculated by adjusting sales and purchases on opening stock, then matched with in-hand stock counted.

The simple formula is Opening stock (+) Purchase (-) Sales = Closing Stock

Periodic inventory management is beneficial from an accounting point of view for small businesses. It doesn’t require any specialized software or hardware. Simple counting of inventory and recording on a notebook or spreadsheet is enough.

Pros and Cons of Periodic Inventory Management

| Pros | Cons |

| Requires no expertise | It doesn’t give any insight into the flow of inventory |

| Doesn’t need any hardware, software, or system | Can’t determine any metrics like COGS, Reorder level, Minimum order quantity, etc. |

| Serves the need of SMBs with a small quantity of stock |

Although periodic inventory management doesn’t add much value to business processes, it’s still widely used in small organizations for verification purposes.

- Perpetual Inventory Management

In the Perpetual Inventory Management method, the stocks are counted and updated in real-time. It accounts for every purchase, sales, damage, and wastage of stock, raw material, works in progress, and finished goods.

This method provides complete information and analytics about the inventory flow. The process of perpetual Inventory management includes:

- Reporting goods in hand

- Adjustments for damage, wastage, etc.

- Sales/ Purchase order entry

- Updating stock on every inventory transaction

Pros and Cons of Perpetual Inventory Management

| Pros | Cons |

| Enables to track real-time flow of inventory | Requires specialized software like an Inventory control system |

| Maintains historical data that can be used to analyse trends and patterns, plan for future needs, etc. | Skilled professionals are required for this type of inventory management. |

| Enables users to create reports of any specific period (weekly, monthly, etc.) any time. |

Almost all organizations use perpetual inventory management. It is an ideal way to achieve transparency, accuracy, and profitability.

Suggested Read: Top 10 Free Inventory Management Software for Your Growing Business

Effective Inventory Management Techniques for Stock Optimization

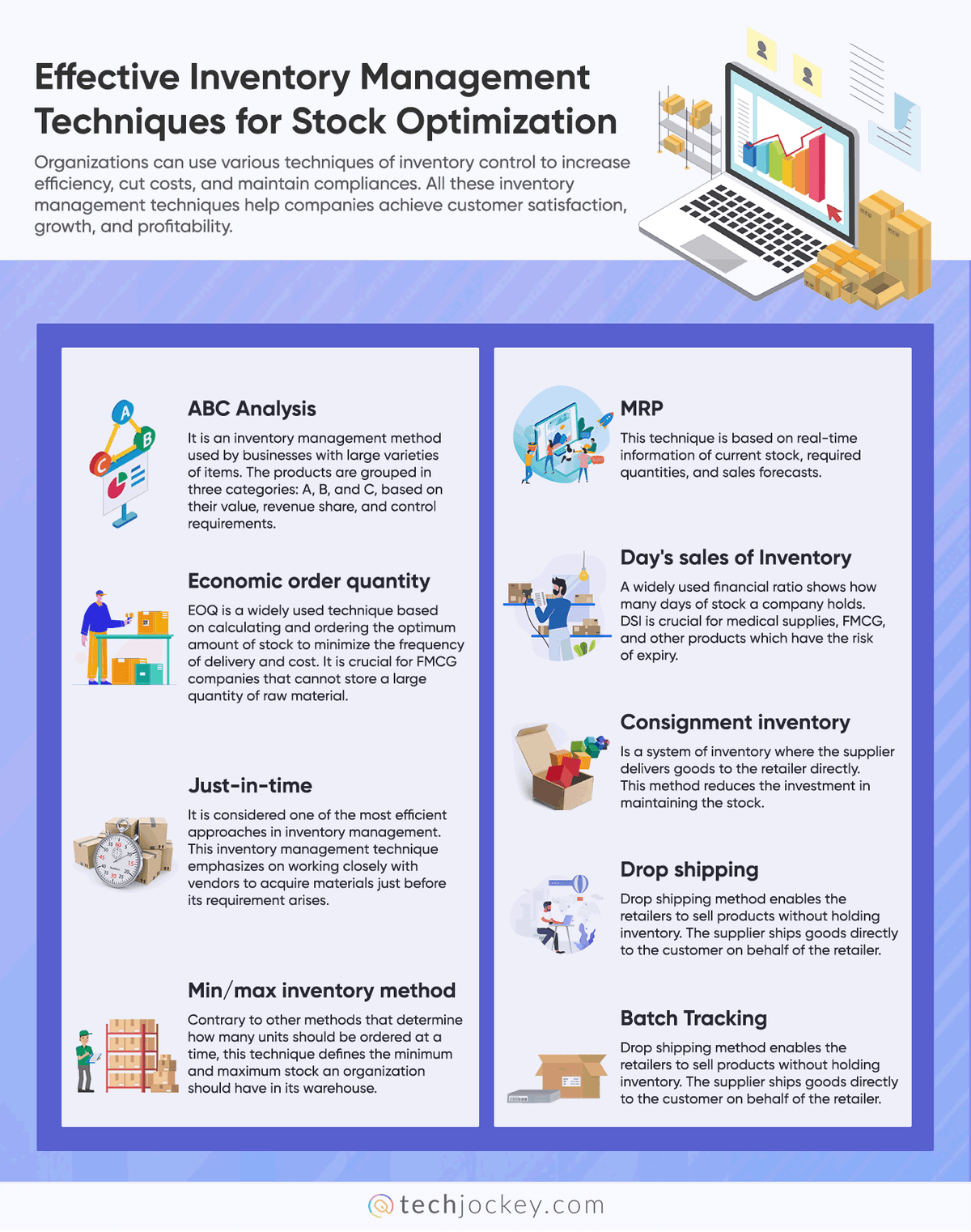

Organizations can use various techniques of inventory control to increase efficiency, cut costs, and maintain compliances. All these inventory management techniques help companies achieve customer satisfaction, growth, and profitability.

These techniques help businesses determine the best order quantity, minimum and maximum stock to be held, and the best approach to inventory controls.

In addition, could use many of the techniques simultaneously for optimum efficiency. Here are a few widely used stock management techniques for stock optimization:

ABC Analysis: It is an inventory management method used by businesses with large varieties of items. The products are grouped in three categories: A, B, and C, based on their value, revenue share, and control requirements. ABC analysis focuses on managing the most profitable products in an organizations’ inventory.

Economic Order Quantity: EOQ is a widely used technique based on calculating and ordering the optimum amount of stock to minimize the frequency of delivery and cost. It is crucial for FMCG companies that cannot store a large quantity of raw material.

Just-in-time (JIT): It is considered one of the most efficient approaches in inventory management. This inventory management technique emphasizes on working closely with vendors to acquire materials just before a requirement arises. As a result, it minimizes the need of inventory management system to block any stock in hand, which reduces working capital, storage cost, damage, and obsolescence risk.

Min/Max Inventory Method: Contrary to other methods that determine how many units should be ordered at a time, this technique defines the minimum and maximum stock an organization should have in its warehouse.

Materials requirement planning (MRP): This technique is based on real-time information of current stock, required quantities, and sales forecasts. It helps determine the order quantity and frequency. This inventory management technique is exceptionally beneficial for a company with fluctuating sales.

Day’s Sales of Inventory (DSI): A widely used financial ratio shows how many days of stock a company holds. DSI is crucial for medical supplies, FMCG, and other products which have the risk of expiry.

Consignment Inventory: A system of inventory where the supplier delivers goods to the retailer directly. This method reduces the investment in maintaining the stock.

Dropshipping: Dropshipping method enables the retailers to sell products without holding inventory. The supplier ships goods directly to the customer on behalf of the retailer.

Batch Tracking: In the batch tracking technique, the location of goods is tracked using batch numbers or lot numbers. This method enables complete visibility of stocks received in a single purchase order. It enables companies to track expiries and damaged products.

There are various inventory control techniques, and organizations can choose one or more of them as it deems fit. Most of the inventory management approaches are proven efficient by thousands of companies around the globe.

Suggested Read: 10 Best Store Management Software for Retail & Medical Store | How Inventory Software Can Help in Real-Time Stock Management for eCommerce

Popular Methods of Inventory Control

Many popular inventory control methods help companies manage their stock accurately and cut costs. Here are a few popular approaches to inventory control and valuation.

FIFO/LIFO Methods: FIFO stands for first-in, first-out inventory management method, which indicates that the oldest stock is sold first. On the other hand, LIFO means the Last-in, first-out management technique where the latest additions are sold away. It helps determine the value of stock lying with a company when an individual item is not tracked.

Weighted Average Method: It is used to determine the cost of items that are not individually tracked. The average price is calculated for all items for a specific period, considering their actual price and quantity.

Specific Item Identification: Every item is identified with its purchasing cost to determine the actual value of inventory. Although this method is highly accurate, it is not practical. It is mainly used by companies with low inventory turnover, like a Car showroom, large electronics, etc.

Period Order Quantity: Items are ordered in a predefined quantity in a specific interval. This is mainly used for items with steady and predictable consumption.

Cycle Counting: This method involves continuous counting of items divided into groups. It is used for physical inventory verification at periodic intervals to assess accuracy.

Bulk Purchase: Large quantities of products and raw materials are procured at once to maintain stocks, save on delivery charges, and avail huge discounts.

Proven Ways to Ensure Optimum Inventory Control

Inventory management is a complicated process involving a lot of manual tracking, automation, data, systems, and analysis. However, keeping up with demand, minimizing losses, and maximizing profits are inevitable requirements businesses must meet for survival and growth.

That’s why proven inventory control techniques should be implemented with both reactive and proactive approaches. Let’s look at some of some inventory control methods that proved to be a game-changer.

- Leveraging the Technology

Technology has changed how companies manage their inventories. Latest technologies like QR codes and RFID tags can give accurate details of any item in inventory in real-time.

Using advanced inventory management systems, companies can now track all their inventory automatically. It allows for many benefits, including more accurate stock rotations, streamlined ordering and receiving processes, less time wasted on manual data entry, and more.

Example: Flipkart and Amazon are India’s most prominent e-commerce players that have increased revenue, optimized supply chain, and increased customer satisfaction by incorporating an advanced inventory management system.

Amazon and Flipkart have implemented QR code tracking in all their warehouses. Staff can use a smartphone and other devices to quickly scan and update the location details of any item in inventory to the system.

- Real-Time Data Utilization

This inventory control strategy allows businesses to analyze the demand quickly, change prices based on stock availability, pinpoint trends, and operate with optimum efficiency. It provides extremely valuable information for managers to maximize their profits through effective decision-making.

A computerized database is continuously updated with real-time data to track the quantity of products on hand. This data is then matched with sales trends and anticipated demand. It helps many companies to price their product dynamically.

Example: Hero Company manages its warehouse of manufactured bikes with real-time data. The company has an average of 400 thousand bikes stored in a single warehouse. It would have been challenging to process orders with manual tracking of models and color variants.

Every time an order is placed for a specific model or color, the exact location of that specific model and color is updated in real-time. This helps the company minimize errors or damage and process orders faster.

Suggested Read: How to Improve Order Fulfillment and Shipping with Stock Management Software

- Forecasting Demands and Sales

It can be difficult to accurately determine how much stock a company needs when the products are seasonal, have irregular sales patterns, or are triggered by specific incidents.

However, analyzing the data of previous sales, growth rate, industry demand, wastage, current incidents, etc., helps the company give them an idea of upcoming demands.

Forecasting demand and sales trends are essential for any inventory control system. It allows companies to understand what products they need and in what quantity to meet the demand. Once demand has been forecasted, businesses would never be over or under-stocked.

Example: Walmart uses data, market research, industry reports, and actual sales trends to forecast future demand. They maintain inventory as per anticipated weekend sales, black Fridays, and Christmas demands.

- Ensuring Up-to-Date Communication

Communication between the suppliers and the organization is a vital step to a successful inventory control process. The best method of managing this communication is through a transparent, centralized system.

It allows essential data and information to be shared quickly with suppliers, which helps ensure a smooth inventory control system.

Communication can also prevent stock outages, as companies will have enough time to reorder. The sooner the company knows that they need more stock, the faster they can reorder and prevent lost sales or excess costs.

Example: Nike had a complicated supply chain as it took orders from the western part of the world, sent work orders to factories in Asia, and then transit the finished goods back from Asia to retailers. Vendors had to place orders six months ahead.

Nike solved this problem by working in close communication with suppliers, manufacturers, transporters, and vendors. As a result, the order status, current stock, and stock in transit are constantly updated for respective factories.

So that manufacturers can anticipate upcoming orders and deliver on time. Up-to-date communication with suppliers and manufacturers helped solve Nike’s inventory management problem.

- Creating Optimum Reorder Point

The optimum reorder point is the exact point at which a company should order more stock. It determines how much and when an organization should order to stay operational without running out of stock.

A reorder point is necessary because it prevents companies from holding their valuable working capital by ordering too much or spending more on delivery charges.

This calculation also considers the time required for production and shipping, giving companies an accurate picture. Thus, it enables companies to never go out of stock while cutting excess costs.

Example: Food Chains like KFC and Dominos maintain their inventory to avoid stock outages or excess stock. They order the optimum quantity of materials to serve fresh food to customers without going out of stock.

- Minimizing In Hand Stock

Having excess stock is much more dangerous to profitability than running out of stock. The longer a stock sits on the shelf, the more are the chances of expiry, obsolesce, and damage.

Besides, storing goods costs companies extra rent, and it also acts as an obstruction. The bigger problem is the locked capital that could be better used in other areas of business promotion.

A smaller inventory on hand is beneficial to the business as it lowers storage fees, reduces natural loss, and prevents companies from the risk of obsolesce damage or theft. It also reduces the working capital required to run the business.

Example: Computer manufacturers like Sony, HP, Lenovo, etc., all maintain minimum inventory to reduce cost and risk without going out of stock. This helps them boost production only when necessary, and they are left with minimum obsolete models during the declining phase of their product.

Suggested Read: Understanding the Role of Software in Inventory Management

How Does Inventory Management Software Help with Effective Stock Controls?

Inventory management software is computer system software designed to help organizations keep track, manage, and generate their inventory. The idea behind inventory management software is to advance the tracking and reporting aspects of an organization’s supply chain to reduce costs and maintain control over inventories.

Inventory management software optimizes your inventory control with the following three methods:

Single Window Operation: With an inventory management system, you can monitor, locate, manage, and generate reports on your inventory through a single window.

Streamline Workflow: Inventory management software streamlines all the inventory management processes, reducing manual errors and increasing efficiency.

Integration: Inventory software integrated your inventory with other business systems like accounting and POS. It eliminates multipoint data entry and automates repetitive tasks.

Suggested Read: Benefits of Inventory Optimization Software – Revolutionize Your Stock Management | What Is Inventory Accounting & Why Integrate Accounting Software with Inventory Software

Conclusion

Inventory management has transformed from a back-office process into an entire system. It involves monitoring every aspect related to the movement of products in and out of the organization.

Inventory control could be the difference between the success and failure of a company. Any company aiming for long-term growth and a superior supply chain must optimize its inventory with selective inventory control techniques.

Related Categories: Supply Chain Management Software | Logistics Management Software | Warehouse Management Software | Courier Management Software

Rajan is pursuing CA with a keen interest in trends and technologies for taxation, payroll compliances, Tally Accounting, and financial nuances. He is an expert in FinTech solutions and loves writing about the vast scope of this field and how it can transform the way individuals and businesses... Read more