The Role & Benefits of ERP in Supply Chain Management

The supply chain is one of the most hectic and equally important processes of a business. It is a major factor that decides the success of your business.

So, you don’t want to mess it up.

With your business, your supply chain also scales, which gets complicated to handle manually. It takes up your resources, time, and strength, but even then, you won’t be able to streamline it completely.

Here, implementing an ERP becomes the only solution. So, let’s discuss the role and benefits of ERP in supply chain management.

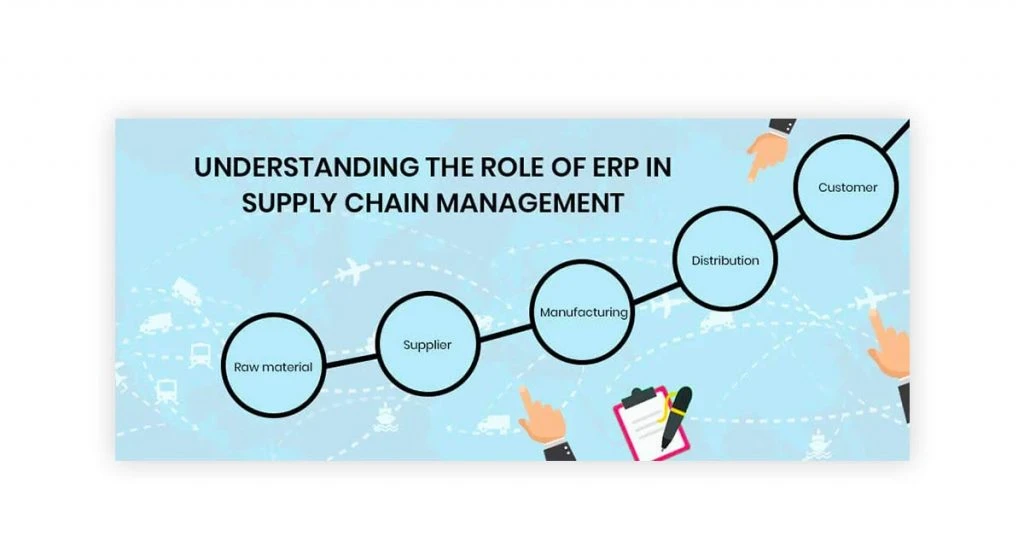

What Is ERP in Supply Chain Management?

An ERP in supply chain management helps businesses to manage day-to-day activities from manufacturing to distribution of goods. Its implementation in the supply chain helps your business to ensure resource availability, fulfill orders timely, reduce costs, optimum utilization of resources, etc.

What is the Role of ERP in Supply Chain Management?

Supply chain management is a complex business process that involves everything that comes between the manufacturing and distribution of goods. It is the core of your business that is related to customer satisfaction.

The SCM process involves vendors, logistics, tight timelines, number of order deliveries, etc. But handling all these manually in a growing organization leads to errors and inefficiency. Here, a well-implemented ERP can come to your rescue.

An ERP in supply chain management can streamline your process with features like order scheduling, real-time reporting, collaboration capabilities, analytics, security, etc. It ensures that your business experiences a seamless supply chain while maintaining optimum customer satisfaction.

Suggested Read: List of Logistics and Supply Chain Management Software in India

How ERP Helps Manufacturers with Logistics and SCM?

Further, supply chain management is an integral part of manufacturing, and ERP software is essential to achieving profitable incomes.

Supply chain management ERP software helps manufacturers efficiently manage purchasing, inventory, demand planning, transport, warehouse, and customer support. It also helps in managing relationships with third-party vendors.

In addition to this, Supply chain ERP offers a risk management module that allows manufacturers to prepare for demand fluctuations. It enables you to take the right action at the right time and avoid market fluctuations. ERP for manufacturers provides a holistic view of operations and helps manage suppliers and resources at a low cost and time.

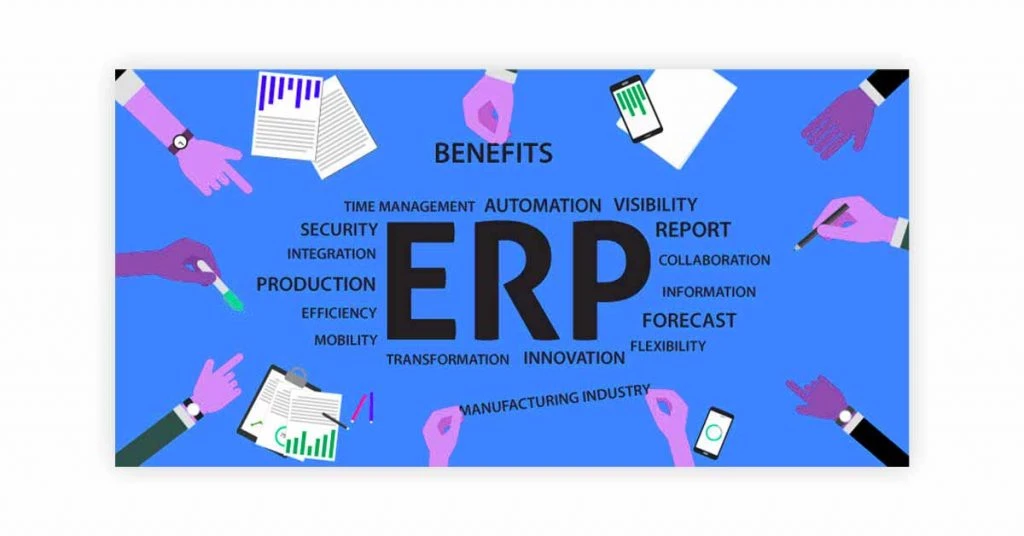

Benefits of Integrating ERP in Supply Chain Management

Efficiently Fulfilling Order Demand: Implementation of ERP automates order scheduling. It provides real-time information on the production status that helps allocate resources as and when required. Also, you can streamline and track the delivery process to prevent any bottleneck.

Better Coordination Between Businesses & Vendors: ERP in logistics and supply chain management keeps the business and the vendor connected in real-time. When your business receives the order, your supplier will be notified. This gives them the time to meet your logistics requirements on time. This ensures that there is no shortage of raw materials.

Avoid mishaps with Increased Transparency & Visibility: ERP system supply chain provides clear, detailed, and real-time data into your business operations. This helps managers understand and identify what is going on in terms of operations. These insights help in rectifying issues and taking appropriate actions to avoid bigger problems in the future.

Manage Supply Chain in Real-Time with Cloud-Based Infrastructure: You can take advantage of the cloud ERP system in supply chain management to access the system anywhere, anytime. Compared to on-premises ERP SCM, cloud ERP offers better data security and mobility.

Enhance Customer Satisfaction & Retention: ERP for supply chain streamlines processes and operations in your warehouse. It enables your business to successfully run a smooth supply network, which ensures a timely order delivery every time. This builds trust amongst your customers and leads to repeat orders and retention.

Minimize Human Errors with Automation: Automation means minimal human intervention in routine tasks. For instance, ERP for supply chain automatically requests for restocking the inventory when there is low stock. In this case, there is no scope for someone to raise the request manually, which eliminates the chance of any human errors.

Use Forecasting & Analytics to Make Data-Driven Decisions: Manufacturers can use business intelligent features like real-time reports and data to identify trends. These reports provide a broader view of how different processes work, their strengths, and shortcomings. This analysis helps decision-makers understand and identify issues and take data-driven actions to overcome them.

Be Prepared for Rainy Days with Risk Management: With features of reporting and forecasting, business leaders can access previous data. Based on the available data, they can foresee coming challenges and be prepared. However, in risks that are beyond human control like the pandemic, the ERP SCM helps teams connect better and enable successful order delivery.

Suggested Read: Checklist for Successful ERP Implementation: Challenges & Best Practices

How to Choose Best ERP and Supply Chain Implementation?

Ensure Compatibility with Current Systems: While selecting an ERP for supply chain, test its compatibility with your current systems. Although, you might need to make some tweaks to fit the new supply chain. These include data migration, customizations, and configurations to suit your new ERP system in supply chain management.

Check if the ERP Fits Your Industry Needs: Identify what features you want in your ERP for Supply Chain Management. Do not opt for generic solutions, rather go for something that caters especially to your industry needs. For example, if you are into pharmaceuticals, look for an ERP supply chain software that specializes in maintaining data safety.

Flexible ERP for a Scalable Business: Adding an ERP system supply chain will be a long-term step in your business operations. You need a solution that grows and scales with your business and its requirements. So, cloud ERP for supply chain would be a better choice for you. It makes it easier for you and the vendor to implement and upgrade.

Great Support from a Reliable Vendor: Your supply chain ERP vendor should be supportive from the beginning of your partnership. The vendor should be willing to understand your business requirements and guide you accordingly for the perfect ERP solution. Moreover, you need a vendor who is available and supportive enough to take on new supply chain management challenges with you.

Offers Maximum Third-Party Integrations: Select an ERP in logistics that can integrate with popular third-party solutions. For creating a smooth supply chain management, the software must support shipping, EDI, and third-party logistic integrations.

Suggested Read: How Does Inventory Management Help with Stock Controls?

Disadvantages of ERP in Logistics and SCM

High Implementation Cost: ERP in supply chain management is a costly affair, especially for small and medium-sized businesses. However, if you go for a cloud ERP, you can choose the monthly payment plans and upgrade whenever required.

Other Resources Required in ERP Customization: Your work doesn’t just end after paying the ERP supply chain vendor, rather it starts from there. Next, you need to customize the solution to your business which requires time, effort, and dedicated human resources. Often organizations don’t realize this process adds up a lot to the overall cost.

Hesitation in Adopting the ERP Software: Moving to new software like supply chain management ERP can be challenging for some users. Employees get comfortable in the way things have always been, which makes their personal and company growth stagnant. But with proper training, this transition can be done smoothly.

Takes Time to Get Full Benefits: Implementing an ERP in supply chain is a complex process. Its process includes deployment, ERP customization, data input, employee training, and more. It is a long process till you take complete advantage of the supply chain management ERP software.

Suggested Read: List of Best Manufacturing ERP Software Systems

To Conclude,

The integration of ERP in supply chain management streamlines the complete process and makes it more efficient. The benefits of supply chain management ERP software are endless including order scheduling, vendor coordination, real-time access, increased customer retention, and more.

But, always ensure to choose the supply chain ERP that fits best with your industry and the nature of the business. Also, consider the support provided by the vendor, third-party integrations, reliability of the vendor, etc.

Suggested Read: What Is ERP (Enterprise Resource Planning) & Why Do You Need It

FAQs

What is ERP in supply chain management?

An ERP (Enterprise Resource Planning) in supply chain management helps businesses in simplifying, managing, and optimizing logistics processes.

Can ERP be used for supply chain management?

Yes, ERP can be used for supply chain management processes such as material planning, order scheduling, integrating transactions, real-time reporting, and more.

What are the benefits of supply chain management in ERP?

The supply chain management module in ERP helps in fulfilling order demand, creating better relationships between business and vendors, forecasting, analytics, etc.

How is ERP related to supply chain management?

ERP in supply chain management contributes towards scaling business processes and streamlining operations. ERP allows you to access all supply chain operations on a centralized platform, which increases efficiency and productivity.

What does ERP stand for in a supply chain?

ERP stands for Enterprise Resource Planning that helps organizations streamline their supply chain and efficiently increase production.

How can ERP boost your supply chain management?

ERP can boost your supply chain management by increasing transparency, providing real-time access to supply chain processes, minimizing human errors with automation, etc.

Related Categories: ERP Software | Manufacturing ERP Software | Retail ERP Software | Supply Chain Management Software | Logistics Management Software | Warehouse Software

Isha’s writing journey started way back in 2018 when she graduated in the field of Journalism & Mass Communication. Since then, she has been writing for all digital and print marketing assets including blogs, editorial reviews, landing pages, emailers, and more. She has contributed her writings to genres... Read more