Summary: If you remain constantly irked by rising costs and production hold-ups, let ERP take charge! Discover in detail within this blog how ERP software holds the key to reshaping the game for manufacturers like you. Learn how ERP streamlines data management, automates processes, and offers immediate insights to enhance production planning, reduce waste, and guarantee punctual deliveries.

In the hectic world of manufacturing planning and control, the pressure to deliver products on time is endless! You often end up sinking knee-deep into production chaos. Deadlines loom, your team scrambles for materials, and that nagging feeling of “there has to be a better way” just won’t quit. That sounds quite familiar, right?

The fact is that we have all been there! But what if you came across a solution that could streamline your workflow, minimize waste, and even help you sleep better at night? That’s ERP, your secret weapon to excel in manufacturing planning & control.

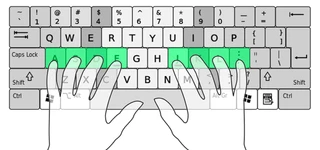

You might have this question in mind: Can ERP help manufacturers with production planning and control with ease, indeed? Here, you should realize that ERP isn’t some ordinary piece of technology taking over your factory.

It’s more like a super-powered organizing hero – a digital filing cabinet on steroid that keeps everything you need in one place. Experience the convenience of accessing real-time information on materials, orders, and production with just a click.

No more panicky searches for lost spreadsheets or relying solely on memory. The system empowers you to make informed and smart decisions, optimize production runs, and finally get those deadlines under control.

So, be ready to bid farewell to the production headache and embrace a smoother, more efficient way of working. This blog will be your guide to the world of ERP, showing you how it can transform your manufacturing life for good. Let’s explore how ERP software can turn your production woes into a thing of the past!

What is the Meaning and Significance of ERP?

If you have a feeling that you’re conducting an orchestra of manufacturing chaos—with inventory disappearing faster than smoke rings, orders piling up like a skyscraper about to collapse, and deadlines whooshing by like a runaway freight train—fear not, fellow manufacturer!

There’s a powerful tool waiting to bring harmony to your operations: ERP, or Enterprise Resource Planning. Think of ERP as your digital maestro. It doesn’t wield a baton, but it conducts a symphony of information, integrating crucial aspects such as inventory, production, and customer orders. It’s like having real-time data right at your fingertips—a transparent view of your entire operation.

Suppose you need to know if you have enough of a certain material to fulfill a new order; ERP can tell you that in a flash. And if you are struggling to figure out how to schedule production runs without creating bottlenecks, ERP production planning can help you optimize that too.

Here’s how the magic works: ERP streamlines communication, eliminates information silos, and empowers you to make informed and smart decisions. This translates to reduced waste, smoother production flows, and ultimately, a sigh of relief.

All in all, it’s a powerful tool that can give you a significant edge in the competitive world of manufacturing production planning and control.

How ERP Helps with Manufacturing Planning and Control

ERP, or enterprise resource planning, can be best defined as the central nervous system of all your manufacturing operations. It’s a desirable piece of software that connects all the crucial aspects of your business—inventory, production schedules, customer orders—on a central platform.

You can also name it a digital filing cabinet on steroids that stores real-time data pertaining to everything you need to make informed and viable decisions and keep your production running without a hitch.

Here’s how ERP’s potential can help you conquer the production chaos and become a master of manufacturing planning and control:

1. Crystal Ball Planning

No more flying blind! Renowned ERP solutions like Cyrus Biz let you see into the future. By analyzing historical data on things such as sales trends and production times, this software helps you forecast demand and plan production accordingly.

Cyrus Biz ERP

Starting Price

Price on Request

This means you can simply avoid costly stock-outs or overproduction and ensure you have the right material on hand to meet customer needs.

2. The Efficiency Enhancer

Production bottlenecks can slow down your entire operation like a clogged drain. Cyrus Biz ERP production planning solutions help you identify these bottlenecks by analyzing real-time data on machine utilization and worker schedules.

With this special knowledge, you can optimize production runs, streamline workflows, and get the most out of your resources.

3. Material Matchmaker

You may feel like you are playing inventory whack-a-mole. That’s when Cyrus Biz ERP takes the guesswork out of material management. With its real-time inventory tracking, you can easily determine the precise quantity of each material you currently possess.

This helps you avoid running low on crucial components and prevents costly delays. ERP can even generate automatic purchase orders when the stock dips below a certain level, ensuring a smooth flow of materials.

4. The Deadline Do-Gooder

Deadlines are the greatest bane of any manufacturer’s life. Cyrus Biz helps you stay on top of tight deadlines by providing real-time visibility into your production schedule. You have visibility into the progress of every order, can spot potential delays, and make real-time adjustments as needed.

This transparency allows you to communicate realistic delivery times to customers and avoid those dreaded last-minute scrambles.

5. Quality King

Needless to mention, it’s essential to keep product quality consistent. One of the best ERP solutions, Cyrus Biz, can integrate with quality control systems, allowing you to track defects and identify areas for improvement.

This proactive approach helps you prevent quality issues before they become problems, ensuring your products meet customer expectations.

Conclusion

There is no need to settle for manufacturing disorders any longer! Top-notch ERP production planning solutions, such as Cyrus Biz ERP, can be your secret weapon for transforming your production floor from a chaotic orchestra into a well-rehearsed melody.

The smart system functions as your digital conductor, ensuring a seamless flow of information between inventory, production, and customer orders. It will give you real-time data at your fingertips, allowing you to forecast demand, optimize production runs, and eliminate costly bottlenecks.

ERP empowers you to make informed and smart decisions, minimize waste, and finally conquer those looming deadlines. So it’s time to seize the opportunity for smoother, more efficient manufacturing planning & control. Say goodbye to your production worries once and for all!

The Techjockey content team is a passionate group of writers and editors dedicated to helping businesses make informed software buying decisions. We have a deep understanding of the Indian software market and the challenges that businesses face when choosing the right software for their needs. We are committed... Read more