Summary: What is the cycle time in production? Is Takt time the same as cycle time? Should takt time be more than cycle time? We have tried to answer all possible questions around takt time vs cycle time vs lead time so that you can optimize the production cycle.

What happens after a customer place an order? The customer wants the delivery as soon as possible and is even ready to pay extra. On the other hand, the business is challenged by fulfilling customer orders quickly. From order production to shipping and tracking, many things could go wrong when dealing with large order volumes.

Inventory management is one of the primary activities of retail businesses. When done right, it can improve customer satisfaction and help beat competition. Measurement of lead, take, and cycle times is widely done for process analysis and improvement.

By taking actions to optimize take time, cycle time and lead time, businesses can reduce inventory waste and stock build-up, prevent out-of-stock situations, decrease storage and delivery costs, improve customer retention, and more. This article discusses the difference between takt time vs cycle time vs lead time, along with the ways to calculate their values and reduce them.

What is Lead Time?

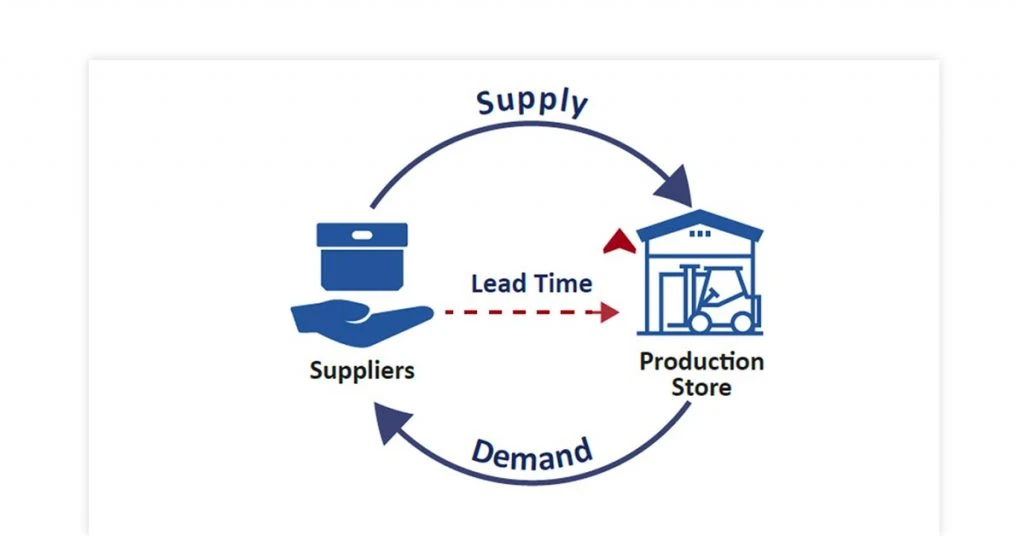

Lead time in inventory management meaning is that it denotes the period between the time of product or service request raised by a client and when the order is delivered. It is an external process that can be viewed by the involved clients/customers.

Lead time is a measure of the speed at which your business fulfils a client request. Lead time can take hours or days depending on the demand, production, shipping obstacles, and other factors.

Its value impacts the time needed to refill inventory and the amount of stock required by the business. Higher lead time means a need for more stock items in inventory.

How to Calculate Lead Time (Lead Time Formula)?

If you face issues in calculating inventory lead time, you can use a calculator. The basic formula is discussed here. Based on the results, you can take relevant measures like shortening the supply chain to reduce it.

- Manufacturing

In the case of manufacturing, this is the amount of time taken for manufacturing a product after a merchant place an order, starting from procurement of raw materials to completion of the final product. This value includes the time to acquire, manufacture, and ship goods.

Lead time = pre-processing time (planning) + processing time (procurement and manufacturing) + post-processing time (dispatch)

- Supply Chain Management

In supply chain management process, lead time is the sum of reordering and supply delays.

Lead time (LT) = Supply delay (SD) + reordering delay (RD)

Supply and Delay

Supply delay refers to the period between ordering inventory items and when the shipment reaches warehouse. The point at which the supplier receives an order is known as After Receipt of Order (ARO).

Supply delay (time taken by the supplier) = Order Delivery Date – Order Request Date (Lead Time ARO)

Reordering and Delay

Reordering delay is the time gap between a fulfilled order and the placement of the following order.

This is the period when retailers must wait before ordering supplies. To ensure order delivery even before stock replenishment, retailers maintain a buffer or safety stock. Reordering delays are higher for slow-moving products that are rare or highly expensive.

- Retailers

In the case of retailers, Lead Time= Procurement Time + Shipping Time

Lead time is crucial since it is used to calculate safety stock and reorder points.

Safety and Stock

Safety stock is the value of the inventory threshold to cover up supply or reordering delay. It also considers demand fluctuations due to sudden shortages, weekends, holidays, weather disturbances, discounts, changes in wholesale costs, etc.

Safety stock = (Maximum daily sales*Maximum lead time) – (Average daily sales*Average lead time)

Reorder Point

Reorder point is the inventory level that, when reached, lets inventory managers understand that they must reorder.

Reorder point = (Lead time * Average daily sales) + Safety stock

What is Cycle Time?

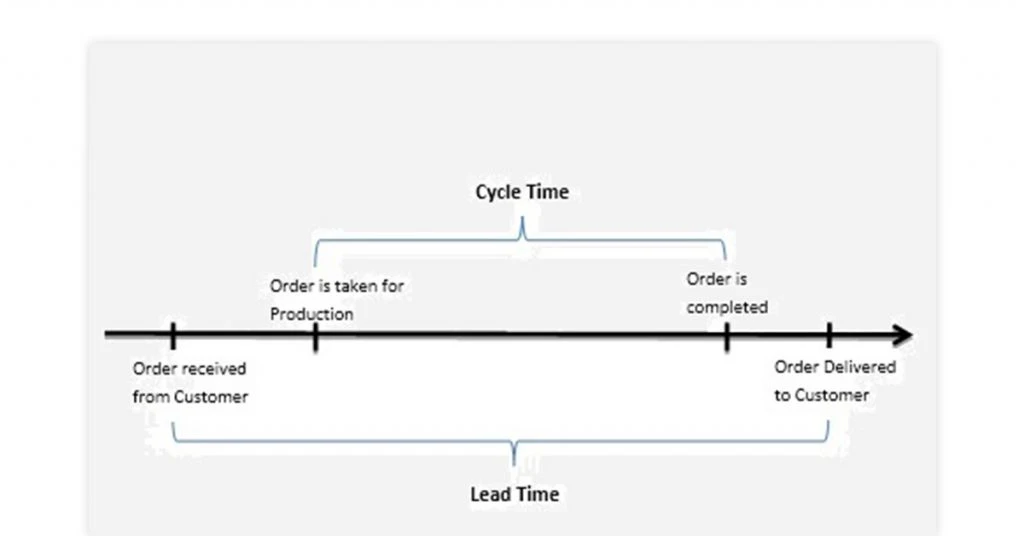

Inventory cycle time is an internal process that represents the time required to convert raw material into final products. For manufacturers, it is the amount of time to produce one unit of inventory stock. For retailers, it is the time taken from the arrival of a product in the warehouse to its sale.

Its value is necessary to determine the frequency of inventory replacement. It helps businesses understand the time taken to complete one product cycle or the time taken during the complete inventory use.

Even if the customer has placed an order, cycle time will only include the time when production to fulfil the order begins.

How to Calculate Cycle Time (Cycle Time Formula)?

Cycle Time = Net production time available/ Number of units produced

Decrease in cycle time by adopting better production measures causes a decrease in lead times. Cycle Time in Inventory Management helps in attaining better productivity, and hence, higher production volume. However, there should be no compromise in product quality if you want higher customer satisfaction and profit margins.

What is Takt Time?

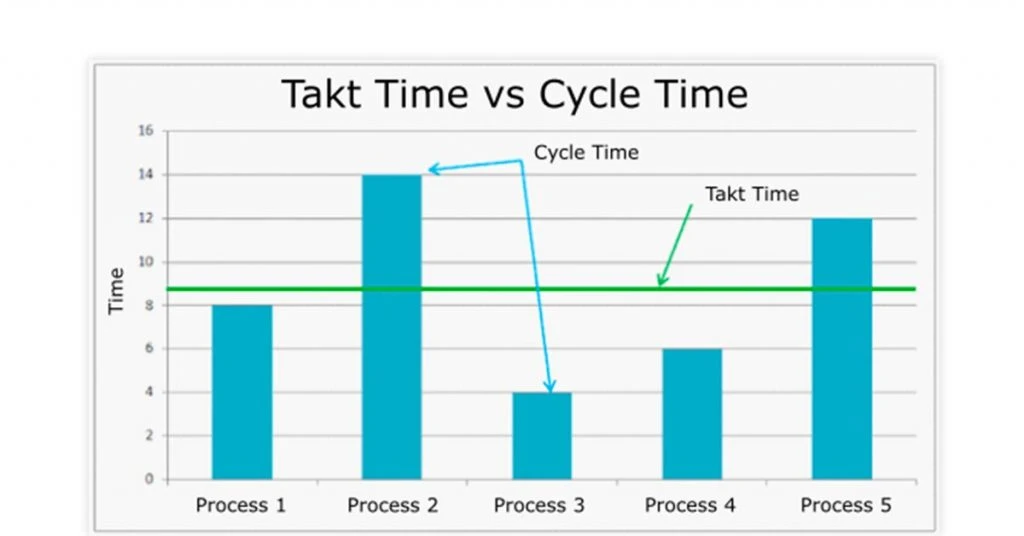

Takt time is the average time elapsed between the starting times of manufacturing two consecutive product units. It is the rate at which products must be maintained to meet the volume of orders at any given time.

Companies can deploy new machines and hire more staff to speed up the production process and meet customer demand.

How to Calculate Takt Time (Takt Time Formula)?

Calculation of takt time should be done in advance depending on the production capacity of the business and demand forecasts. The calculation assumes constant demand. In case of demand fluctuation, takt time needs to be adjusted.

Takt time = Available production time / Number of units ordered (Customer demand)

Cycle Time Vs Lead Time in Inventory Management

Lead time measures the time elapsed between order and delivery. While cycle time is a part of lead time that measures the time taken from the beginning of work on the unit till it is ready for delivery.

If the difference between lead time and cycle time is high, it often indicates the unused inventory.

| PARAMETER | LEAD TIME | CYCLE TIME |

|---|---|---|

| Definition | Lead time measures the hours or days from order placement till delivery. | Cycle time measures the hours or days in which a unit is produced. |

| Visibility | It is visible to consumers as it involves operations outside production too. | It is visible to only business management as only production related operations are included. |

| Goal | Helps to get an overview of production/ sales processes. It is used for measuring arrival rate. | Helps to get an idea of the production rate. It is a measure of the completion rate. |

| Analysis | To analyze reasons for customer’s wait for the solution | To study the demand for the solution. |

Cycle Time vs Takt Time

Cycle time is the actual time in which a business completes the production of a unit. Whereas, Takt time is the theoretically estimated time that tells by when a company should ideally finish production. Let’s understand the difference between takt time and cycle time.

Cycle time must be as close to TT as possible to avoid under or overproduction. Issues like employee absence, machine breakdowns, quality issues, etc. can make it challenging to keep the cycle and takt time close.

If cycle time is greater than TT, it means that the company cannot meet customer demand. If cycle time is lower than takt time, it could mean that staffing is more compared to the demand.

How Can Software Help with Lead Time Reduction?

For monitoring lead time and taking measures to reduce it, you must have accurate data. Managing inventory manually or through a spreadsheet is time-consuming, error-prone, and unreliable.

To see the best results and optimize lead times, you must invest in good inventory management software irrespective of the business size.

- Automated inventory management

Inventory software helps in automating inventory-related processes and setting delivery dates accordingly. It saves time by automating repetitive processes and creating a scope to plan purchases, stocks, and orders for maximum profits. It also decreases the chances of customers changing their preferences or switching vendors.

- Real-time data tracking and alerts

Inventory management software allows real-time transactions and inventory tracking across multiple platforms and locations such as warehouses, storefronts, and more. This data helps with better financial and inventory planning. Businesses know the exact time the product was ordered and delivered.

They get alerts when stock items reach the reorder point. Hence, losses from understocking and overstocking are minimized. And due to the reduction in stockouts, customers receive their orders faster.

- Transparency

The software ensures visibility in all supply chain processes and helps prevent inaccuracies and delays. Businesses can make changes to avoid bottlenecks and anticipate disruptions that may cause delays. With What-if analysis, businesses can figure out the impact of these changes in advance.

- Accurate sales forecasts

Inventory management software provides reliable sales forecasts based on past data. Hence, businesses can provide suppliers with precise estimates of the quantity of required stock items in advance and reduce the time for receiving items from suppliers.

This strategy helps strengthen the relationship with suppliers and effectively manage the order fulfillment process.

- Integration with existing systems

Inventory management software integrates with existing systems like point of sale and accounting software to streamline processes across all business units.

Connected systems help in faster order delivery and small businesses can gain an edge over their competitors. Large businesses can manage huge volumes of orders easily without process delays.

Conclusion

This in-depth comparison of lead and cycle times should clear up any confusion you had. Use inventory management software if you want accurate values of lead and cycle times. If you are still not using inventory management software to reduce lead times, check out different solutions available at www.techjockey.com.

FAQs

Is cycle time and lead time the same thing?

Cycle is a part of the lead time. Cycle time measures the rate of production in a manufacturing process. Lead time includes all processes leading up to the final manufacturing stage.

What is the difference between cycle time, takt time and lead time?

Lead time covers all the product development stages starting from taking orders to making the final delivery. Cycle time is the average time taken to complete the production of a product. Takt time is the estimated time allotted to a manufacturer for finishing a product to meet the client’s demand.

Is lower takt time better?

Takt time would depend on the type of demand that is there in the market. High demand products would require high takt time and lower demand products would need lower takt time.

Is takt time same as cycle time?

Cycle time decides what a manufacturer can do whereas takt time is about what needs to be done. Takt time is based on the client demand and the effort of a manufacturer to meet their expectations. Cycle time is what decides how long a product would take to complete.

How is takt calculated?

Takt time can be calculated by dividing the given production time with customer time. Technically, it is about dividing the net production time with customer demand.

How is lead time calculated?

In order to calculate the lead time, you need to add a sum of shipping time, manufacturing time and procurement time.

Why is lead time important?

Lead time is critical to the success of a business as it eliminates the wastage involved in manufacturing a product thereby fastening the product manufacturing process. The faster a product is manufactured, higher would be the customer satisfaction rate.

Is takt time always in minutes?

No, takt time could be in hours or seconds too.

Related Categories: HR Software | Applicant Tracking System | Payroll Tool | Attendance Management Software

Ayushee is currently pursuing MBA Business Analytics from SCMHRD, Pune with a strong background in Electronics and Communication Engineering from IGDTUW. She has 2 plus years of full-time work experience as an SEO content writer and a Technology Journalist with a keen interest the amalgamation of business and... Read more